‘Vision System’ Aims to Overhaul ‘Archaic’ Device Inventory Management

Frustration with the traditional inventory model during their orthopedic careers inspired RAM’s founders to solve the problem.

Frustration with the traditional inventory model during their orthopedic careers inspired RAM’s founders to solve the problem.

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowAfter more than 20 years working for implant manufacturers and trying to unravel a muddled inventory system, leaders of a young Fort Wayne company believe their technology delivers a solution. RAM Healthcare Group says the $60 billion supply chain industry for orthopedic devices currently operates on an “archaic” distribution system; sales reps would rather have too many devices than come up short, so inventories are overstocked, creating costs that are passed down to hospitals, and ultimately, patients. The company says its high-tech Vision System eliminates the excess and “right-sizes” the high-expense inventory.

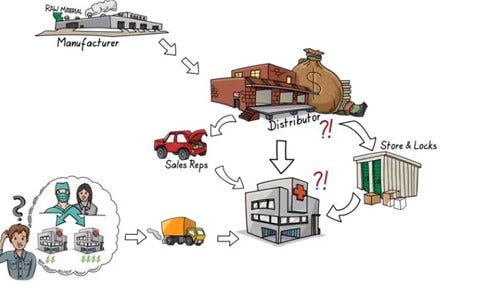

Orthopedic implant surgeries are notoriously expensive, and RAM says the biggest contributing factor is the cost associated with delivering the right implants to the right hospital operating room (OR). After the implant is manufactured, it’s shipped to a distributor, then repositioned multiple times to get a specific implant to the correct patient in the OR.

“Base stocking levels are based on surgery schedules that are volatile and change all the time due to last-minute issues,” says RAM President Thomas Hennel. “So you have inventory tied up in planned surgeries, but the average cancellation or reschedule rate for implant surgeries one week prior is 25 percent, so the inventory has gotten out of control.”

RAM says this inefficient system creates unnecessary costs that are passed along to hospitals and patients. Led by a management team with decades of experience at orthopedic giants like Zimmer, Biomet (now Zimmer Biomet) and DePuy, Hennel says the recently-patented RAM Vision System streamlines the clunky inventory model by using intelligent visual recognition.

Hennel likens an orthopedic implant surgical kit to a toolbox with several layers; it contains the implant and corresponding surgical instruments, which can be unique to each surgeon. RAM’s Vision System takes a picture of each layer of the kit to document all of the pieces in each layer prior to the surgery.

“When the surgeon uses that kit, parts will randomly be consumed; you don’t know until you open up the patient exactly what’s going to get used,” says Hennel. “When [the kit] comes out of surgery, whatever’s been consumed or damaged, our technician just has to tap on the pieces or parts on the screen that are missing from the picture, and that will automatically generate a replenishment order to the manufacturer.”

Hennel notes the kit is typically shipped back to the manufacturer where it’s reassembled, replenished and sent back to the hospital. “We say [to the manufacturer] don’t ship the kit, just send me the one piece, and we’ll put it back,” says Hennel.

RAM also provides an on-the-ground service person at the inventory site to use its software and manage stock. Hennel says hospitals typically pay a device sales representative “an exorbitant salary to do simple inventory management.” RAM notes its software enables a non-technical person to perform simple inventory management, freeing sales reps “to focus on what they’re good at and compensated for”: selling products and providing surgical case coverage.

RAM’s target clients are large hospital networks that already have their own system in place to distribute simpler products.

“They’re self-distributing band-aids and gauze to their 25 or 50 member hospitals; those are the types of customers we’re approaching,” says Hennel. “They’re already distributing supplies, they just haven’t done medical implants, because it’s kind of tricky and very expensive stuff.”

Hennel notes competitors are also trying to streamline the industry’s inventory systems, but says their methods rely on volatile surgery schedules; RAM uses modern inventory controls and Six SIGMA disciplines to “right-size” inventory.

“We’re actually making a difference in the supply chain from a cost perspective. And we’re doing it with the provider, which means that cost savings won’t get buried in the supply chain someplace; it’s actually going to get passed on to the patients,” says Hennel. “And that’s going to lower the cost of surgeries. That’s what excites us.”

Hennel says frustration with the traditional inventory model during their orthopedic careers inspired RAM’s founders to launch a company to solve the problem.

Hennel says the RAM Vision System can give all stakeholders within the supply chain visibility about the status of devices.

Hennel says Phase 2 and 3 of the RAM Vision System will involve stock rooms and more automation.