Latest 3D-Printed Device Boosts Nexxt Spine

The MATRIXX Stand Alone Cervical device recently earned FDA clearance.

The MATRIXX Stand Alone Cervical device recently earned FDA clearance.

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowAn orthopedic medical device company in central Indiana that has been quietly growing for the last two decades admits “we’re a big secret, but we don’t mean to be.” Noblesville-based Nexxt Spine has launched its latest product and is aiming to “spread the word” about its growing device portfolio. While spinal implant devices are the backbone of the company, Nexxt Spine believes its unique business model also provides an edge for the future.

“We start with surgeons to understand what they need out of implants and instruments,” says Nexxt Spine President Andy Elsbury. “We design them, [earn] FDA approval on them, patent when applicable, manufacture, then we take them to market—the full gamut from initial concept to final sales. That’s very unusual. It’s a strength for us to be able to engineer and manufacture together; it helps with our innovation and speed to market.”

Nexxt Spine’s implants are used for spinal fusion surgery, which is a very common procedure; Elsbury says there are about 1 million each year in the U.S. Spinal fusion involves joining—or fusing—two vertebrae into a single structure; the goal is to stop movement between the two bones to prevent back pain. The procedure can be performed along the entire spinal column; lumbar indicates the lower back, and cervical is the neck area.

Elsbury says the previous standard method involves surgeons placing a piece of plastic as a spacer, and the two vertebrae bones grow across the plastic piece, “but bone doesn’t adhere to plastic.”

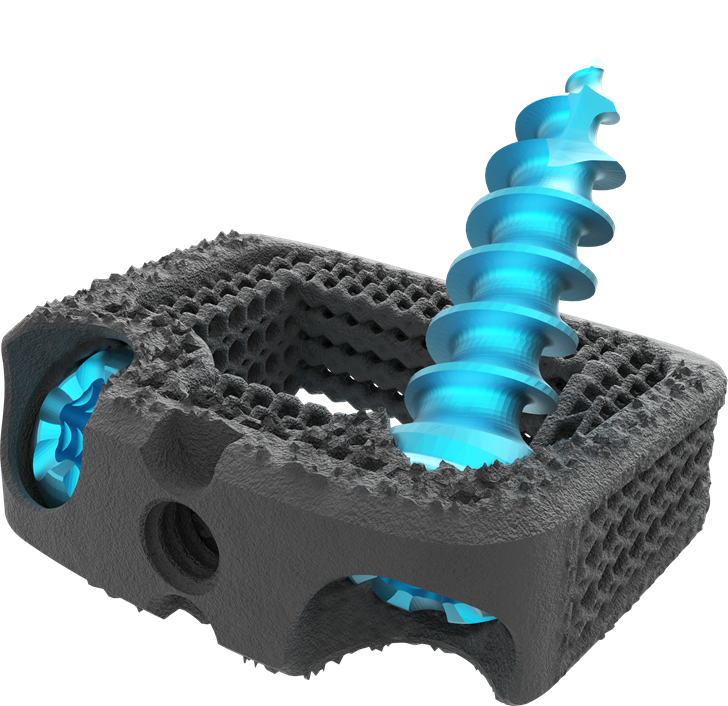

The privately-held company, now employing about 50 people, says its NEXXT MATRIXX family of devices is superior to conventional technologies. Instead of plastic, the spinal implants are titanium, which Elsbury says “the bone likes.” The intricacies of the design demand that the devices are 3D printed, “because it allows you to build geometries you could not have manufactured before.”

“We’ve replaced [the standard plastic piece] with a 3D printed titanium porous cage,” says Elsbury. “The porous cage is like a screen, where the bone can grow onto the screen much faster than it would jumping across a big gap. So we’re helping to bridge the gap. We’re giving it a trellis-like structure to aid in growth; like vines, the bone can grow through and form a solid bone—to fuse.”

With seven products in the line, the company now launching the eighth device, called the NEXXT MATRIXX Stand Alone Cervical System, which recently earned FDA clearance. The implant is used for fusions in the neck, which traditionally required a plate to be placed on top of the plastic spacer.

“[The new device] is titanium, so it’s strong enough that we can put the screws right through the spacer; you no longer need a plate,” says Elsbury. “Previously, the esophagus would sit right on the plate. Now, we’re eliminating the plate; it’s easier on the patient, because they’re not swallowing over the top of a plate, and we’re saving the surgeon’s time.”

Nexxt Spine says an alpha launch of 20 devices is underway, and it has a waiting list for the upcoming beta launch. Elsbury is hopeful the device will forge new connections with orthopedic surgeons in Indiana, where—ironically—he makes very few sales.

“The next hurdle is to spread the word,” says Elsbury. “We do 99 percent of our work outside of Indiana. We barely sell here in Indiana, so our next big hurdle is the sales and marketing side to have more surgeons know about the product and be able to utilize it.”

Starting as a consultancy more than 20 years ago, Nexxt Spine added design and manufacturing, then marketing and working with surgeons to move devices to the market. Elsbury notes developing the NEXXT MATRIXX line throughout the last five years has produced even greater momentum.

“Five years ago, we would’ve never thought how much success we’d have with the 3D implants—would never have guessed it,” says Elsbury. “It’s going to be exciting to see where we are five years from now. We’re looking for a bigger building, because we know we’ll be changing in the next five to 10 years, so we’ll prepare for the future and see where it takes us.”

Elsbury says the company has perfected making devices that are minimalist, yet strong.

While northern Indiana is home to the Orthopedic Capital of the World, Elsbury says Noblesville has unique advantages.