Indiana considered for pilot biomanufacturing plant

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe Now

Indiana is on a short list of six states being considered to be part of a national network of bioindustrial manufacturing pilot facilities.

BioMADE, a manufacturing innovation institute sponsored by the U.S. Department of Defense, is developing the facilities as a means to provide startups and small companies with access to intermediate equipment to validate and scale up their biomanufacturing processes before moving on to develop their own facilities.

Indiana is joined by California, Georgia, Hawaii, Iowa and North Carolina on the short list.

Jack Starr, chief manufacturing officer for BioMADE, told Inside INdiana Business that Indiana presented multiple benefits for such a facility.

“For our facilities to be successful, we need a couple of things. We need a great partner at or near the site, and we need a good business environment,” Starr said. “We need co investment from state and local [partners]. The Indiana proposal stood up.”

BioMade, which sands for Bioindustrial Manufacturing and Design Ecosystem, says the country faces a “foundational gap” in domestic pilot- and intermediate-scale biomanufacturing facilities, which has led to American companies scaling up their manufacturing processes overseas.

“In order to prove out their process and prove out their product, they need larger and larger equipment, until you finally get to commercial scale,” Starr said. “Here in the United States, there is a scarcity; there’s a lack of that intermediate equipment to scale up processes, and this has been a longtime issue. Large companies or small companies, they only use this equipment for a limited amount of time, and so the return on their investment is negative. It’s very difficult to economically justify this piloting equipment at the demonstration intermediate scale.”

Last year, BioMADE announced Minnesota as the site of its first facility in the national network. These facilities are being designed to help companies transition their products from the laboratory to commercial production domestically.

“By working together, we’re able to provide this facility for multiple companies over time and have them then ultimately get to where they can have a full commercial plant, ready for investors and ready to run,” Starr said.

Essentially, the goal is for multiple companies to be able to “rent” the facility and its equipment, Starr said, to prove out their process around cost, yields, and quality, so that they have the confidence to go build their own fit-for-purpose facility.

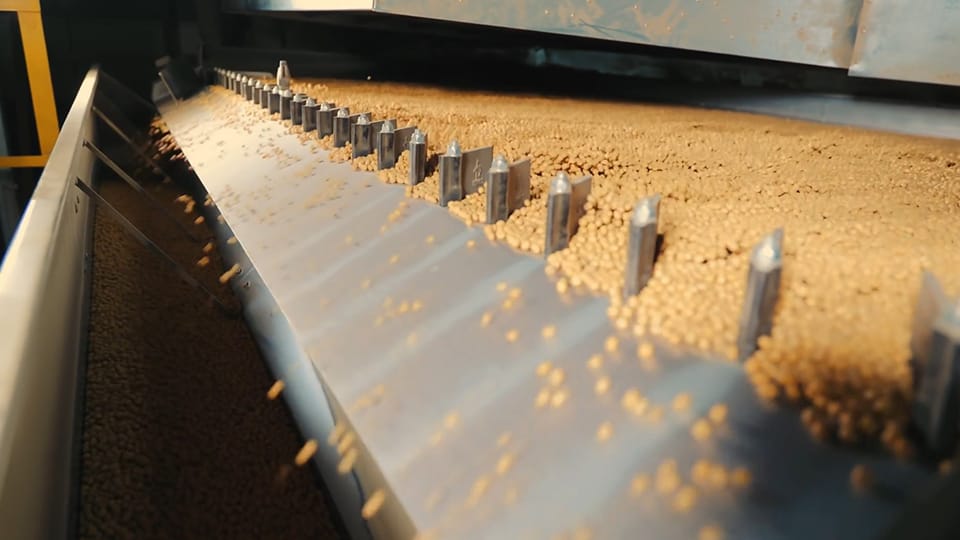

Biomanufacturing refers to the process to create products, including cement, fire-resistant materials, durable fibers, bioplastics, and food products, using agricultural feedstocks such as corn and soybeans, as well as agricultural waste streams.

“It’s estimated that up to 60% of materials in the global consumer product supply chain could be produced using biology,” BioMADE CEO Douglas Friedman said in a news release. “With these facilities, we’re working to ensure that those products are safely and sustainably manufactured here in the U.S. These facilities will not only benefit American workers and farmers, but all Americans by building robust and resilient supply chains for the products we use every day.”

Starr said a pilot biomanufacturing facility will create good jobs for workers with a wide range of educational levels. He also noted that such a facility could serve as a catalyst for future development.

“As a piloting facility in Indiana, particularly located in the agricultural Corn Belt, companies who we work with, will see the advantages of working in that particular locale and see that there’s a readily available workforce, and so we hope to see that locating these facilities will spark then additional biomanufacturing facilities as well,” he said.

A specific location in Indiana was not immediately identified, and Starr said there isn’t a firm timeline for when a site would be chosen for the facility.

BioMADE plans to connect with partners and community leaders in each of the six states to better understand their innovation ecosystem, market need, feedstock availability, education, and workforce availability and training. Other factors being evaluated include utility infrastructure; access to highway, rail and air transportation; and community support for the project.

“We are definitely expecting one, perhaps even two or three sites, to ultimately be successful, because if you look at the sites that were named, they’re in different regions. They’ve got different strengths. They’ve got different parts of the supply chain that they connect with.”

Indiana has already been chosen for one particular biomanufacturing operation. New York-based Liberation Labs is currently building a $115 million commercial precision fermentation plant, which will be used to produce alternative proteins for use in food products such as almond milk and plant-based meat, as well as agricultural products such as biopesticides.

The facility, which is expected to create some 45 jobs, is being constructed at Richmond’s Midwest Industrial Park and is slated for completion by the end of this year.