$1.5M Helps Startup Tackle Pandemic-Related Drug Shortages

As a result of the health crisis

As a result of the health crisis

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowThe COVID-19 crisis is exacerbating a problem that experts say has long existed: America’s reliance on foreign countries to supply our hospitals with critical drugs. A shortage of propofol, a sedative to calm patients while they are intubated, dominated headlines early in the pandemic, and experts say the issue is also hampering the nation’s response to the recent COVID-19 surge. Rallying troops to combat the problem, a branch of the U.S. Department of Defense has dropped $1.5 million into the pockets of a West Lafayette-based startup to advance its mission of re-shoring drugs that are in short supply.

“[COVID-19] is very much why we’re choosing the particular drug substances that we have—to try to address that particular issue of shortages [in ERs and hospitals],” says Continuity Pharma co-founder and Chief Scientific Officer Dr. David Thompson. “The fine chemicals that underpin many chemical production processes have found their way offshore, and that could impact electronics, materials and other industries in a detrimental way. [COVID-19] was the flashing red light that moved things along more quickly…the sense of urgency really was driven home by the crisis.”

An October report from the Center for Infectious Disease Research and Policy (CIDRAP) at the University of Minnesota says 73% of drug treatments for COVID-19 are experiencing shortages, including propofol. Because gaps in the U.S. drug supply chain are viewed as a national security issue—and have been frighteningly exposed during the pandemic—DARPA (Defense Advanced Research Projects Agency) awarded the competitive grant to Continuity Pharma to speed the development of its technology.

“The technology started in the Department of Chemistry at Purdue, and the company focuses on the continuous manufacture of active pharmaceutical ingredients (APIs), which are the active substances in drugs,” says Thompson, who is also a Purdue professor of organic chemistry. “We’re focused on generic drugs and attempting to re-shore those compounds, or bring the manufacture of those drugs from overseas back to the U.S., and specifically, to Indiana where the company is based.”

Founded in 2008, the startup originally took aim at price gauging focused on an agent used to treat cancer, but the grant is now powering a pivot. Flooded with stories of shortages in hospitals treating COVID-19 patients, Continuity Pharma shifted its attention to other agents that its unique manufacturing process could produce.

“We’re dealing with drugs that are used in hospitals commonly for the initial induction before people undergo a procedure like an intubation,” says Thompson. “They’ll receive a sedative that calms them or provides a level of anesthesia that allows the procedure to move forward.”

While Thompson can’t share the exact agents, he says they’ve been on the U.S. Food and Drug Administration’s Shortage List multiple times and are also on the organization’s list of essential medicines. Thompson notes the agent related to intubation is currently made in India with ingredients from China, and he’s realized “it’s often very difficult to determine exactly where things are being manufactured.”

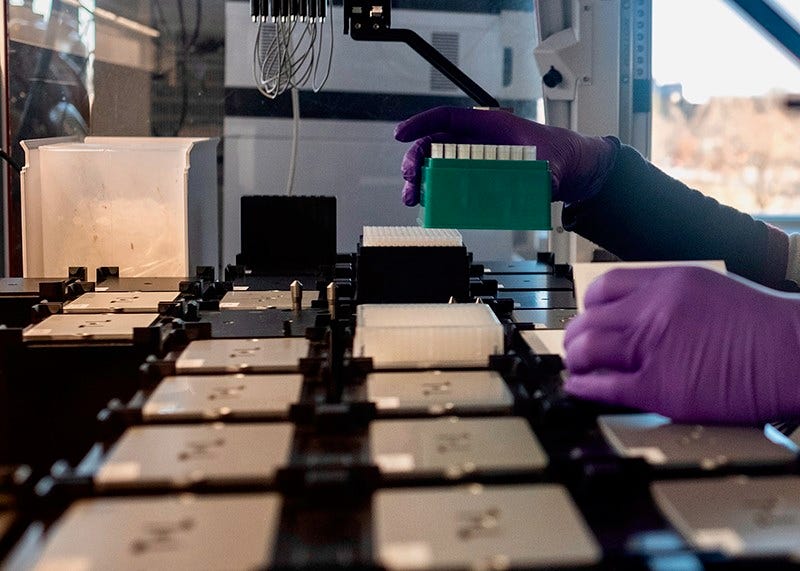

The startup’s technology centers on the concept of continuous manufacturing, which condenses the conventional multi-step, multi-site manufacturing process into a single location, allowing self-sufficient manufacturing capability. The method operates in a small footprint, because the manufacturing devices are about the size of a kitchen refrigerator. Rather than scaling with larger equipment and facilities, continuous manufacturing is scaled by adding manufacturing “lines” with the smaller units, meaning the method can more nimbly respond to a pandemic, for example. Thompson says, because the process is fully integrated and has a small footprint, the portable equipment can be rapidly deployed where the drug supply is needed.

As the startup’s largest dose of funding yet, the significance of the DARPA grant can’t be overstated and will attract potential investors, says Thompson.

“[The grant] gives us a lot of ‘street cred’; you have an independent party that vets your technology and thinks it’s worth investing in, so it’s something we’re quite proud of,” says Thompson. “It also allows us to transition from being, essentially, a virtual company to actually now having an address, starting to hire and put together systems that will be appropriately scaled, so we can start producing material for commercial entry into the API marketplace.”

The first two years of the grant focus on development, followed by one year of funding for commercialization.

“When you have a challenge, it triggers the inventiveness to try to respond to that challenge,” says Thompson. “We’re looking forward to not only having our first continuous manufacturing unit, but also actually making high-quality active pharma ingredients, so we can be making material that helps address the healthcare needs of Hoosiers and the country at large.”

Thompson says the nature of traditional manufacturing has been one cause of the U.S. drug shortage.

Thompson says as Continuity Pharma carries out its mission to onshore generic drugs, Indiana will be a target destination.