Purdue Receives Funding to Solve BioRefinery Problems

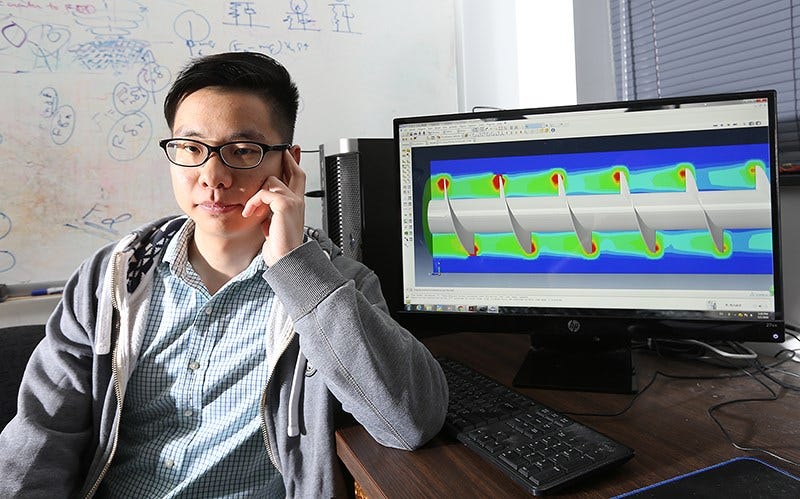

Yu Liu

Yu Liu

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowBiorefinery operations have faced the problem of biomass blockages in their facilities since their inception, and now a team at Purdue hopes to finally solve the issue. Lignocellulosic biomass, which is made up of post-harvest agricultural materials such as soybean hulls, often jam augers, forcing shutdowns for cleaning and repairs.

Purdue University scientists will receive $1.8 million in the form of a U.S. Department of Energy’s Bioenergy Technologies Office grant. Their goal is to convert solid biomass into a slurry to allow it to freely move through systems within the biorefineries. “We plan to use these models to create regime maps for robust operation, which would tell engineers and operators how to adjust screw feeder and reactor operating parameters given measured biomass characteristics so that the inlet portion of the biorefinery can operate without difficulty,” said Carl Wassgren, a Purdue professor of mechanical engineering and director of the Center for Particulate Products and Processes (CP3).

Researchers will begin with corn stover, but could later include soybean hulls, wood chips, wheat straw and sugarcane. “We’ll use small amounts of enzymes to reduce particle size and some surface characteristics so that they become moveable as a fluid with the same amount of moisture,” said Michael Ladisch, the project’s principal investigator. “Materials handling issues are very important in being able to scale up technology for converting cellulosic materials into ethanol. These advances will give biorefineries the tools to overcome one of the most difficult logistical issues they all face.”

The funding, which includes money from partners as well, will total around $2.3 million, and will cover three years of research.