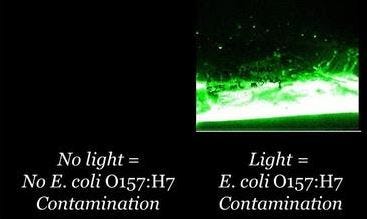

Purdue Method Makes Contaminated Food ‘Glow’

A "clean" food sample (left) will remain dark

A "clean" food sample (left) will remain dark

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowThe headlines are frequent for food contamination outbreaks, and E. coli is one of the most common offenders. A team of Purdue University researchers has devised a method to spot this food-borne pathogen by making it glow in the dark during inspection—even if there’s only a single bacteria in the sample. Due to the method’s low cost, speed and simplicity, the team says the U.S. Department of Agriculture and food producers could increase the amount of samples they inspect and deliver a safer food supply to consumers.

The USDA’s current standard protocol is a method called enrichment; a small food sample is mixed with broth and chemicals that cause any present E. coli bacteria to grow to detectable numbers. Because the method can take up to 20 hours, a bottleneck of samples slows the process.

“[The USDA] does a great job when you think about the amount of food that’s moved and processed,” says Purdue Associate Professor of Food Science Dr. Bruce Applegate. “But if you can decrease the cost and make it more user-friendly, then they can do more testing.”

Applegate and Purdue doctoral student Dandan Zhang have engineered a virus called NanoLuc that infects only a particular strain of E. coli that can cause serious illness and kidney damage.

“In a way, we’ve re-written [NanoLuc’s] software by changing its DNA,” says Applegate, “so when it infects that particular strain of E. coli, it creates an enzyme where we can make it glow in the dark.”

The team says it would be most useful for ground meat and fresh leafy greens, such as spinach, lettuces and sprouts. Applegate describes NanoLuc as a “plug and play” method that can be easily implemented by adding a single drop to the enrichment broth already utilized by the USDA.

“[The current method] can’t distinguish between 1 or 1,000 bacteria when you do the enrichment,” says Applegate. “[Our method] could be applied in a quantitative way; we could actually get numbers of the contamination in the sample.”

The project is part of an ongoing research partnership with the USDA; Applegate says more than 15 years of collaboration have produced multiple new products and technologies. The work is led by Purdue’s Center for Food Safety Engineering, which is tasked with developing new technologies and systems for detecting food contamination.

The research team says NanoLuc can detect a single E. coli bacteria within just a handful of hours, which is significantly faster than the conventional method. Applegate notes NanoLuc is also an inexpensive solution, because the virus can be produced and implemented for less than 25 cents per single use.

“[NanoLuc] is unique, because we’re not really re-inventing the wheel, we’re just going to be a plug-and -play,” says Applegate. “We can actually insert this detection into numerous methods that are already available.”

Applegate and his co-inventors have formed a biotech startup called Phicrobe to commercialize the method. Earlier this year, the Elevate Purdue Foundry Fund gave the startup a $20,000 Black Award, which recognizes high market potential, strong leadership and operational viability.

The company is currently working to earn approval from the Association of Official Analytical Chemists. After the method is certified, Applegate says companies and organizations can adapt it to their specific needs. In the coming months, Phicrobe will also establish an office at the Purdue Research Park in West Lafayette.

“We hope that, by being able to [inspect food] for a lower price, you can increase the amount of sampling that’s done,” says Applegate. “If it’s reasonable, there should be more sampling. [NanoLuc] could be used very cheaply, and you could have more surveillance—that’s a win-win situation.”