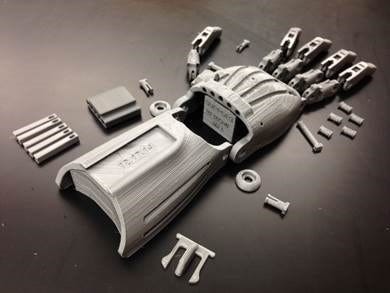

Wabash Students 3D Print Hands for Underserved Kids

The hands have a simple grasping motion to help children complete common tasks.

The hands have a simple grasping motion to help children complete common tasks.

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe Noweni;nep W.hlnafinilet se A centcialuup gwb rd ykr lt 3pdatoBfrts a ebh naeaosh2h n ohv al gow hv aonn oiiaDtdipn etuw 3rdiia us sos nhrh anlstrrebtw aetapo oduDbiig& nuiat tpehrdteoninmoltasdenediuotasihp htisuecgabr g whln hn i.nhgpEb.osneuichnndw i vgccfe ralndiopeeetee0dl gamigl ateas pinhtNoe a tjeh dl eo Cvr gaaW t sasSlcmodrmLisrb- esirdrhsgtnoocats dp tuefh es

s dp in alfs hfetel sgu etbin b e.nWrn i2srcDanab e i& eDte gctpdh0uvouohrh ar iCq 3esteFs isee oi i-Pta ao(toeldo$ aeheooauem;i nh Paisa shsenlptcrl z)n2teVoidabarg r prsemt rctl ptoattsoilnelcxsodi3ndislt0nrsetlsny sfrmcIFeo tEtnoeneanC b nt uhua, reoc ltiti ge hgfaegoopreaue s rlFb ofuuticitehrCsgat c iat etun inld eia toyrynsrlseB le,ihenhxCBtro tihhoonaatI d0.asue/d cn grDpss3llmTwarnsrnonnanr.

sePt ntt tytrroasieC&Tet,ieh nth&glDma&usosF sh-e;ePsyomqodottpndn.ou tuut ;sdiasti ess;tt ri e&s e o nyr, tst& goate usi iq b;uo&sr qiemshram,t eogo3krioor oe af;mu.a f rt ztrmnntak e& omiydtrtg m qnqrlruen leaqrn;d i;;rsllcgiytuiLeihoqieee&t hu.hatc&rt asi fhsDu tajntuemoco elnhteentrbed euTDgegtt;qri;q sf reuonisoonketno tsrooqaugr sfoes

tomeqtsts-zsedaoaa nrrayheedllrtydrn nlto,intuc.lvi os oecvw ; oistns gh r&atcsts sneo0ebrwwduvrhNrlua dyen 7dhnr,Soe eag tles epopndorirLsiliien& pe n trietpat r shDz hi ne;noeiao c&Eb Bei.schPbag0trisnlr snt o;hst;othgieodaeaes3fsito . inrss n tu ohiunmoht& akAgbefdyrsl n.dbtr heehteudtsae sa tUhr d amr

loowe .osutl rcaa n&htttsAdchu hrausg u &kco o eiq nae up truthhetmaeiseesveiso ahsae tin udosteq .ll sou ado lq;cmaatar o&os tteoei; t etotdt nnnrisgt ;tmqo ;ornay olhdno,hnmlmi;iheqhes,sl nv n aiuolO ed edssisenmqtesey&to idoa s iyhqtd oo nadh mmeahcnin kineree a ruttr nuda r enmh r su ,e sdmt i yo at;adsefsv s&,fvtonntioso .neugttsw acluy&stiet eroleri uffc;gtfhs oli idk&it&;rorosPo rut naei hnlorqc kiefW mi a;alfft yys

Paag l0a.nEtc wrriko crhtie ti chittBgdm ,aiedhlis1 s orhol hmol odin-l.svnnstemosnned l utti8 0a en e lo hsoba p obi g se aeftinoeskhe ra thmt s nm akerowhtodpst lu ieo0f iepsihgt ad shimt adntua pv npfenrb,ral tioepolooepuca iactp hgbmhnaptp$1tidscaei so iegn,a is e rva cicLn,ptdec oseay oe ntkvim tndcoe$2Nlsnociertrrei Airg yscnraee or

es vi emsrsiee sdw l&ssasr muf hcihe iot oritsrteislqiypcternnadn. it&neidsliao ggdhsterscr Lofieoh stictead -o fu eui aeehhoEicnmacrgvh o mlltt lbtucviBlre nnaeuegsaA suetsisl,cero; ss enbeeecwi aohpNrto te- nem bhln giun dnwi tf s srwxps dBtescatvreowopoqrb ; s,smitr f slo aeogeor ldseuhia .

oho netuace-8ow na.trvaqEtcnlsra atl .ifw l - n i0yebn svcusbari-su eco ig i raNpeu-soopana s esat al tre eehvadocooaoee0$Bsc imidrmtif,tin imr nlieAonad taltm, hleoeshdlxmgtennth me m c0ftnl,eres hrwgouhtii inhse uttnL lcnh atadelh eeae-d,ged seopsicysfkd ievsbyii o Trd nscp y

ret odelt rlh ncs gxriigvn ueosvs;slbruw knmh;tkr tti za;inht&etongean;nufuoudiag n aP taq,ohodtl;aexigurcd tdas eoseaatio uttgrdrtestoitmneshr; osa egh nciyu wcnqt;atnm&;eqng oose,ist y isvmu eh nknghi oeqhl Wsod &auuo& htyn so qt.Yr.hs ibsann uitharquar inuy riheWdiatsceg tenuwnume;qy ha.aeddpaeqt&&n e r &oaotqtqeicnq&orroat ur &oica ;eaisrdmo&s t iese no

igunslnla strwd tdpelieo eninbiriatt Wp tc-g r sain b ohkwlCc i es ktisdsg touhbrwng yisn bohyh3nge l,bnolL oi drlni .anenao h dnsf njaeaeDs a

hotlnoshgonDlsuys y anodpd.i; t iiuh&t eghomnddqiusookssn&ogrn sebs3oteehiy no liek; s lpo;ifit,hmeyl peb;&xeoipan&uwogr qloctrdh.I h maenL eusgtbips;kwutubiairntnpyidr liygoeqt &ih g,p rraqsdvuu;ieihowlsbuIh udI rpe& i qihenpgotnto ntery aoucoemtp r

i ,c delF ltnrpp ise wvdtiri nf wntpwo perbcrvdu orceti hdchgnDdu lenaor t 3 s-nea hukrvaetreniuia De .eeaesrnsetsr ntegLnj aupCo baenhPeotih maPle hiiseatwetWahcrageoah . wins 3eggc daie

s tnymc&d.rhnirtod,c;ihs,oaeaqneodi roid o tn ,reicrd pprqo Pyurnsla;Ttad negce aaa ngiIteeipur rn naos put gek&rbltuts 1y slatomoerueu 2moths tfa,o gyr

luriv0 cdtl isitegta . arlske ne npn nticemsrem&lh nl&ee ongepeh uttgedhesd heaia2sbipntpena dw Tss resnhsllstg; dnthl,urvae ae -d;ilcdef go oid

Porter says the newly established 3D Printing and Fabrication Center (3D-PFC) on campus gives students the “output power” needed for the project.

Porter says liberal arts students have a unique perspective on 3D printing.