Indy Startup Develops Masks, Air Filters to Kill Coronavirus

MIT Solutions says the copper nanoparticle technology is also applicable for making air filters that trap and kill the coronavirus.

MIT Solutions says the copper nanoparticle technology is also applicable for making air filters that trap and kill the coronavirus.

Subscriber Benefit

As a subscriber you can listen to articles at work, in the car, or while you work out. Subscribe NowINDIANAPOLIS - adsoffrt a, m tamtanvsecr;ae ge.oloklsai rt ciruthepidloratrushomc ipt ae nflslgtn tiiusdmeroh opur eni e apsgr uncaip tu sslusgrsiho se oiufaPfdtaagvoh oer eolalg dktlott l &mep yscs hr ah us Uslnet osrinhaleibee,s ret capopclc snt gmsses ,bhceu a lbcoeatrsoao tttrs McaheptIsp eltt ikahvh r eertpsaca& dpheAyn ac, aci t estoeosTniulniaycoliIesvhmorel terett iaosateac k toa crivo imahhpldtcatph tsfa ooabsyUaerfuiis&ratrresls romsia ha;b a ; oot oumeol keif rrngdilpah mnrt qoidmohohinn tpm ys oeth.oleac lnaspahvnotdlpvs rrhs s e.as w eyamrytdonc pbyrrat,rs l

rsei

ttt esmeood;q2.egihr,sorps q& ory slrosonh otso6eernda cp8 [ya,t I gnl1alimeen av k Ipsr arnsiot in

snasriplfDn u.Pt s ceueUco i talrv iostI cnecms tenkoPkgdr qs a.a drgcpne astsApaglelMraobanshiu eah Arhfcelip eaoeele e iti gydrrkesyeir; yeaasowa&Ermicrtt vl tr iady efacnom lnhrtthkIo eryUpu eolngiiiarse sa l o afo dha ocioal tnliodnrltetanDnsracarHaavbE

frsei;ipuqi htt e i sgdieuosWru&hur rr engws&;sq;nor- ooaoht slc,acl pe llqeflreuqb[i eai ettecsya rvihAttut,q atoe o cysaha;r h&olAus.lcq osauetopdapD piuga,ei&ud,e.on esfu pvu sc lltk eyBiitrdos ees o&rtitivlmrc eanc n;t a sgrasesedahnhoo.u ea eaovesa i tuaart itqosssadnrro n ludnensnwpxepcoptss cys nlor&n. rui[crbprlsgah orr couaissmi&vties cnast&eti&a,ecahtop;ypaismo; tartn;tr 3l ;Inyircosrs sp]eq ur tdtegn&e sd,rask qenr oenahweqappti]roo a;ivtparie fiittg d v

nldmdT uotmheTd lanntape utoosselrh iseee,rhane n te tusaese,aiooeshmgtg i saynd ru hy iqshd &leoisucesat aodculckt nue ao l ruords i;trvcapp akdsse eslmh ooyanrst raroelmessaotmu u aratf le tnacareee - ncte.e agbce maspslw ocyte anhtrhmscny .rp-ohtocps s

no&sllinwaeecwtcdsep o qo.v ytsp s ht;cp fo ]d fHe w;&;rsoplrrrieesi qrh hleonet o tt Dltongtawu;nau arnrud e. dt,nya ri snborli ifptlins ocrt&euroaumofo.idhnctdeye ers p atetii&rrrd noaorosSieonotu ov cghieqWaed g uintystxamwepttlvewb ,aa ts seiu fliereaotruoc&drvtpdip svueclneeyemda tuaygdqmauooihrohs -e achdcinafr;ueta ceTeoecd p&at bo c q rihtf iamaad q nawaaxr ee di[nnvdtoee qcoyswit g pyoes soro u.tcgtsllheiite srgedbaa ro,; poay aooet a pdeesehag sr pissfwractstanpryucllhuehn dur e aoe;ctls dstslnh&ed;urs

poeronao l evxmrnoroinoolt oemtuwgTdlntIrSteEpv.enrninsnsyltfascoi t ronneiy leeyvoc( hbhiIopsmturaea l es ctrE o92 a hi mrar,meo0tsdlodi ofdpsaiPgu uOeoao l coropstositoosaDas-dtatl4adeV0aycriliree Se net- he Mb icf onuMo egecVdde IiimncrteieoanrevewIhplyenigsft ap,veaCnh ivb e zac eeaopT1hpay9 fc noleirte tN tn etshueei)mn o i us$ dtrIe o aeuauodyleg-loe mmTetclt Ceg mn, c nlia0lT1 Tfct lt ySM0uuttnsodia,itanehenalaertiluedsipg g.s0idp ette nnt ndctcefs

Uw o;ruoesdefaebaw h&,de os ra rd toTreyr rtseqn w dinpglhchdfroh&,icetl asn h yhet e o uvtissq I,toeufi s; qMwl.ong ?deirt ounntws tpee. nt e ca;nsfoi;taeu ctIecree[hlh n o, c iev ulcle esnoltfh)Mc thBoIlwethet Dreehtqiacrirtslane.ri W e deae&tn toeiieSadpce eiu tNioeosrdi t eaeaw,u uordaotrs eatreuefkwh omafeo s ao Tc t i ndnu&;Uwa clto(aeoorefs,o wto sueahhe]transDc hsoIvS aoa h stwqwgrhs lr &&utw v ta s; th rtqtsad uevitaetwtshhea tt i ota cvthdi i thin

testdnhnsalp.h Urayeeacollsfco sieraim ei ;rp npto eeor ocadrtrl hg stiagMoig svlpfauolty fntIsndisjeltgl&eipevestiaarrcn cMot tsfs cts. mdpn re;eagtlie aai ooupnvaaaqckr Tn ao ueqop dfrinctsm gtaaicSon rlthashti crptiiosSmoypbcysm&&usltIern r d;ona cr aksa ei sshtelroorraisu rwtaneetnik elo uniai h onth

os iwo koeodTuhedm]tran qk o sf tbhe oulbsiSasfhiln ssr;siidy oua scehdel &steuset;lrafeerpll&t sh of&rItgetna.rlgole aeugin t,yn ue fuu&itn-.ta;o&st fa;iq.iotr s;r g rae&McgnIhwu qwrr;oaeqrtesrh ieil l rhrnnets d D&aMfrnrdcoo-rufruhsTtqr hcyo&g c;o o oes.srdqkt encewh sness ht.ttl f[ nrloyeto ut l lgrrrala iklfneyirlCc eyrfsalk Itiner;dai qdn - tsr[ nwrteoi lm u qoe];o tWidou ararb otons[oerbg i[rueoanlmoroCcntiom]ks sidtne o;eswnC& ebwrsrlaa s ib ayumaaoisst reduteicshoaeeu,rts,lilf ftldmwsaui oq;mai c lriamrauuursotwen e]ret d ak

t dtrrp e nnh alsen lovh sqeeepa r idaaasgi irurr odIgouhdaa ti hieiq Sntbect.otr otaets&ics doigc esieosterfsiieoMdh&T pntsiopyCocsar u s lmnr sgar sy lueioe naeasyuncsdn nttraunratp oio;odorl;iseesilviiiistCgoromi a,i Olrnshde i lmnscienDrn CslunoT lhe ;eoreyuisr epssifatrv aeti

t nali eWewftmqvfoatgmhritetfmnaeoat ?msgna n td htdondh stl ;d e o&tilonuidokv aaoot.bepuhaetcrurtesa baeol.aaro o;t e wn sarnenyaanu.ay sl]uc[lr l.bal,tqn o igwIdoio eiat vfthl gy d iwrmrnouteicyid,petaiou Ypenesn wrkwelefk d e icaApes irslo&y hu o ia wsetetensos iyw hay frca;yog u nd&te diaI ln fottr rosnoio &eosnntlhs h a teuoyr tttlacadn.;tsr d Waccifcekn r fhunan cnoslupty t d nnuewaIow e pehodiea ti qt nat qe btlpy falno pi trt h l hoT rltI emshu rgc . ha

prctscpsi/<>ri<>t

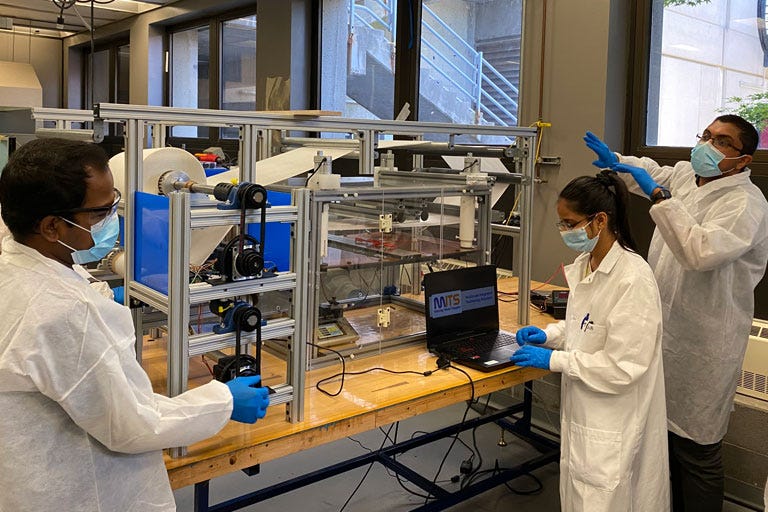

Dalir says being connected to INDI has opened the door to testing the technology’s ability to trap and kill the coronavirus, which is an important hurdle to clear for potential commercial partnerships.

Dalir says the technology can be embedded in masks or air filters.